As technology advances, so has the prevalence of 3D printing. The ease of sending a design file to a printer is unrivaled, and the new possibility of creating complex structures is revolutionary compared to age-old construction techniques. However, as humanity innovates, the waste produced by this expansion is unprecedented. The waste products from modern construction and demolition practices alone are more than twice the amount of general municipal solid waste (Environmental Protection Agency, 2018). So, how can civil engineers attempt to combat the behemoth of demolition waste with their own hands? Through repurposing construction byproducts. Asphalt has been repurposed into aggregate, and recycled materials have been added to concrete mix designs. So, why not add superfluous wood particles (i.e. sawdust) into 3D printing filaments? Wood-plastic composites (WPC’s) are sustainable and environmentally friendly, especially when used with recyclable polymers (Zeng, 2024). The sustainability of fiber-reinforced polymers (FRP’s) is extremely relevant to environmental concerns, but its material performance properties in real environmental conditions are yet to be completely ascertained.

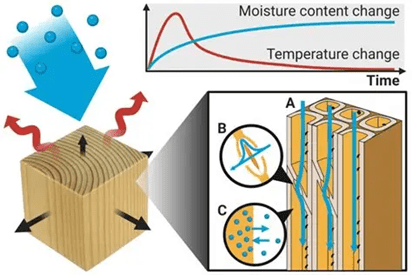

Although, prior research has established that natural fibers like wood influence moisture uptake, diffusion, and dimensional stability in both extruded and molded composites, little has been done to systematically evaluate these effects in 3D-printed wood–PLA systems under orthotropic mechanical conditions. Thus, I’ve decided to add moisture content as a parameter to this study, as well as hydro-degradation. The figure below illustrates the added deformation that water particles inside wood’s meso-structures will cause. The susceptibility of the added fibers in the PLA matrix are a very interesting topic for the scope of this project.

The last few weeks have been very eye-opening in terms of evaluating the overall contribution of my project to the civil engineering discipline. Initially my project focused on evaluating material properties of anisotropic 3D composite specimens printed in different orientations. However, after looking into the current body of knowledge surrounding wood-PLA composites (WPCs), I’ve decided moisture is a very relevant parameter. Due to this shift in scope, my current hurdle is redesigning the testing matrix and looking up relevant procedures (ASTMs) to fit this new direction. The figure above is an example of the new type of testing I will have to do to determine/control the moisture content of the samples before testing.

I believe this change in scope will not hinder me since the basis of the testing is still the same. Overall, I am very excited because this type of research aligns with my interests more (since my major is civil and environmental engineering), and can’t wait to share more with you next month!