One of my main goals while pursuing research is to deepen my understanding of the concepts I learn in class and apply them to the advancement of knowledge. To me, research bridges the gap between theory and real-world application. A perfect example of this was during my Strength of Materials course, where we studied how different structures respond under tension, compression, torsion, and bending.

Above is one of the fundamental diagrams in strength of materials that illustrates how to resolve any applied force into components that act normal and tangential to the faces of the element.

We examined transformations between stress and strain and explored energy-based approaches for determining failure properties. While the course content was fascinating, I struggled to fully grasp some of the theoretical models, especially those involving infinitesimally small sections of beams. Visualizing the mechanics of internal forces and stress distributions on such a micro-level was abstract for me at the time.

However, when I began conducting research related to material failure, many of these challenging concepts started to make sense. Seeing how theoretical models were applied in experimental design and data interpretation provided a new layer of clarity. For instance, when working with 3D-printed specimens and testing them under controlled loads, I was finally able to understand ideas like stress concentrations and modulus of elasticity. That moment when abstract theory clicked into practical reality was incredibly rewarding—and it is exactly why I find research so fulfilling. Reaching that kind of understanding is difficult to achieve through coursework alone. Research provides an immersive, hands-on experience that reinforces and deepens academic learning in a way that is so intellectually satisfying.

As I continue developing my project at Florida State University, I am excited to take full advantage of the resources available. One resource I plan to use is the Innovation Hub, a collaborative space that encourages student-led exploration and creative problem-solving. I’m particularly interested in utilizing their 3D printing facilities to fabricate the specimens needed for tensile testing. I hope to experiment with different infill patterns and reinforcement orientations to study their influence on mechanical properties. This kind of experimentation aligns closely with the goals of my research and will provide invaluable learning opportunities.

Above are some of the 3D printers the Innovation Hub has which are free to access for FSU students.

In addition, I want to explore the High-Performance Materials Institute (HPMI), a multidisciplinary research facility on campus that focuses on advanced manufacturing, nanomaterials, and high-performance composites. I know that HPMI works with continuous fiber printing, which is an area I am extremely interested in. Understanding the methods and tools they use could help me push my own work further, and I’m hopeful that I may have the chance to collaborate or at least gain insights from their ongoing projects.

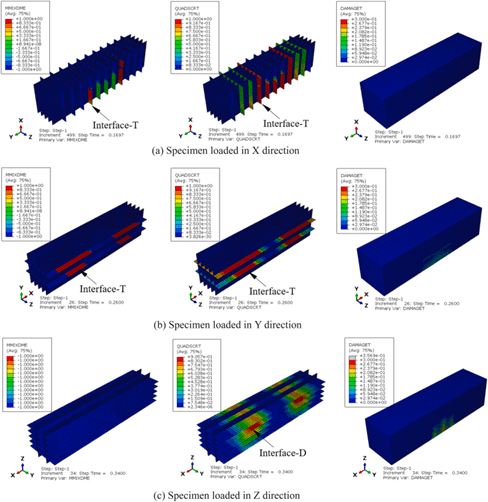

At this stage of my research, I believe the two areas where I have the most room for growth are learning finite element analysis (FEA) software and working with composite 3D printing techniques. While I have experience with basic 3D modeling and printing, FEA is entirely new territory for me. The textbooks and manuals are quite dense, but I’m confident that with time and consistent effort, I’ll develop the skills I need to effectively apply simulation to my research.

This is a photo from a paper on finite element analysis on the anisotropic behavior of 3D printed concrete under compression and flexure. This is very similar to what I will be doing except with natural fiber reinforcements.

Image Credits:

Jianzhuang Xiao, Haoran Liu, Tao Ding, Finite element analysis on the anisotropic behavior of 3D printed concrete under compression and flexure, Additive Manufacturing, Volume 39, 2021,101712, ISSN 2214-8604,

Fletcher, D. Q. (1985). Mechanics of Materials. Holt, Rinehart, and Winston.