Hello! My name is Rameen and I am an undergraduate student majoring in civil and environmental engineering. I’ve always wanted to be involved in research, since pursuing a PhD is my final goal. One day, I hope to be a professor to ultimately pay forward the knowledge I have gained. Thus, participating in and developing valuable research is a key step in my plans for success. I’ve always had interests in combining sustainability and technological advancement, an unfortunately overlooked subject in civil engineering because of the modern race to build faster rather than better, so this project is a way for me to provide another option for faster, precise, and sustainable materials with construction applications. The project I will be working on this summer is investigating the orthotropic properties of 3D printed materials with natural fiber reinforcements.

As 3D printing technology advances, the future of construction is in unprecedented upheaval. The accuracy and malleability of printed materials have much to offer the civil engineering discipline, but material failures have yet to be properly established. Furthermore, with the rising interest in sustainability, the prevalence of biodegradable filaments also increases. This research project explores the mechanical properties of 3D-printed natural fiber-reinforced filaments, such as wood, bamboo, and cork composites in different planes.

Orthotropic, or multidirectional, analysis is necessary because unlike traditional isotropic materials, which fail similarly in each plane, these composites exhibit a directional dependence of their strength resulting from fiber alignment and layer-by-layer printing. To better illustrate, think of the strength of wood when applying a force perpendicular to the grain. When comparing it to a force in the direction of the grain, shear failure is achieved at much less force, making it weaker in that plane. Compared to traditional isotropic construction materials like steel, this failure shows how a natural material like wood is less reliable because of its anisotropic behavior. This material trend makes sustainable development more difficult. Now imagine building up a material layer by layer (i.e. 3D printing it). This would also impact how it fails since it creates a “grain” to the material. Combining the two concepts raises the question of to what extent printed materials would fail if reinforced with natural composites with anisotropic properties.

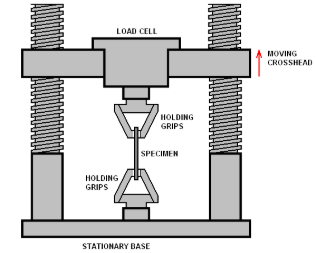

This study will involve mechanical testing (tensile, flexural, and shear) to experimentally determine the stiffness and strength characteristics of printed samples in different orientations, as seen in the figure below. The results will be used to construct a constitutive model that describes their behavior mathematically. Additionally, finite element analysis (FEA) will simulate real-world loading conditions to validate the findings.

By combining experimental and computational analysis, this research will contribute to the sustainable application of 3D printed materials, therefore enabling better design strategies for natural composites in civil engineering applications. Understanding this anisotropic behavior is critical for optimizing its use in eco-friendly structural applications.

The goal of this project is to construct a constitutive matrix of the reinforced filament’s failure properties to further knowledge in this civil engineering discipline. I’m so excited to begin this research project this summer, and hope you enjoy the ride as well!

Image Credits:

Forcellese, Archimede, et al. “Manufacturing of isogrid composite structures by 3D printing.” Procedia Manufacturing, vol. 47, 2020, pp. 1096–1100, https://doi.org/10.1016/j.promfg.2020.04.123.