I have split up my project into three portions: extraction of cellulose nanofibers (CNFs)

from the algae, studying the nanofibers under different observation methods, and finally applying these nanofibers to the pervious concrete.

After I more deeply explored the process of extracting these cellulose nanofibers with faculty, I realized that there is no prior research specifically Sargassum muticum cellulose nanofiber extraction or on the properties of these CNFs, which have a very broad range of applications outside concrete reinforcement (we will be using methods successful with other types of algae). My professors have advised that a detailed process of extracting and studying these CNFs may be time-consuming, and that I may realistically not have enough time in the summer term to test them on pervious concrete. I hope to have my research published in a journal, and finding a successful extraction method and studying Sargassum CNFs should be sufficient, although I do hope we can reach the point where we can test with pervious concrete.

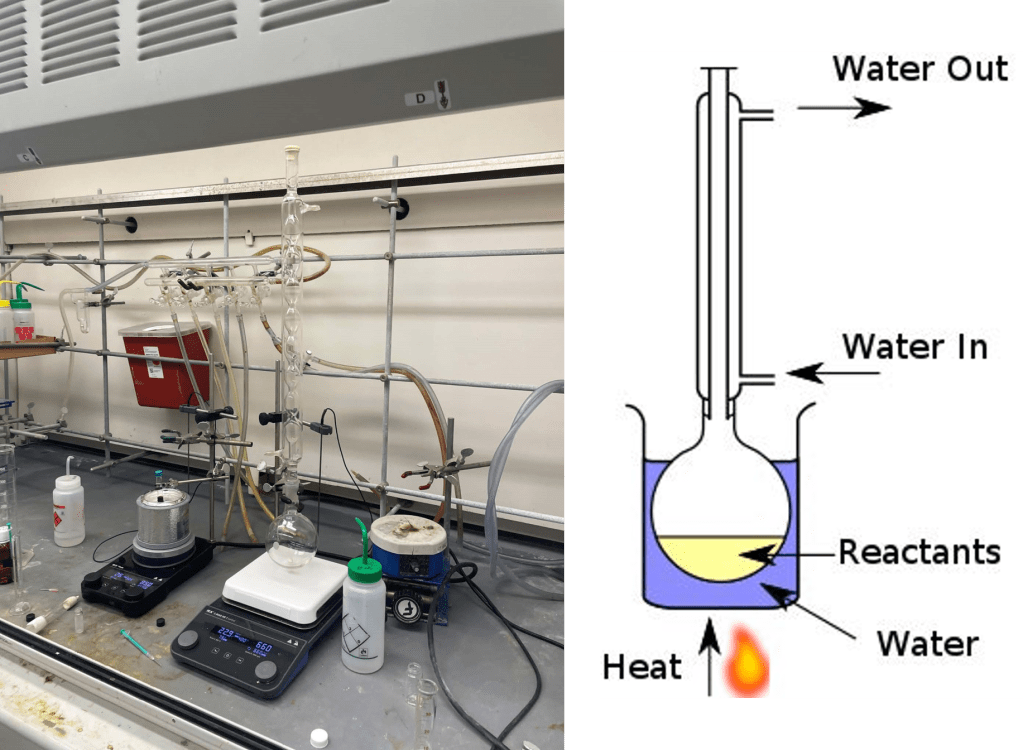

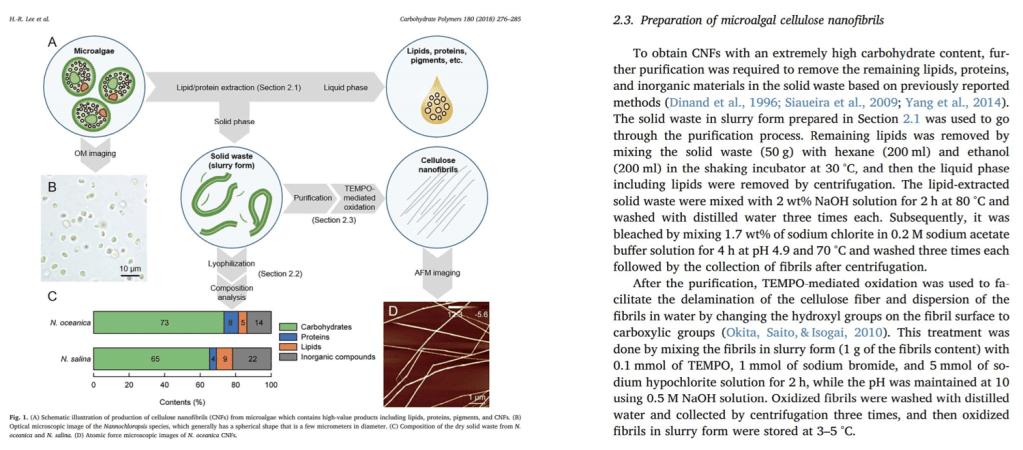

For step one, we will be refluxing (sending the algae through) three different solutions, to bleach the algae and dissolve its lipids (fats) and proteins, leaving us with the cellulose nanofibers. This process is described in an article published in 2017. I have attached an image of the apparatus we are using (in the HSL Chemistry building at FSU), a diagram of the mechanism, and a detailed description of the process.

Another method of extracting the nanofibers that we may examine is the TEMPO-oxidizing method, explored in articles from 2018. We may wind up comparing these methods.

After successful extracting the nanofibers, we will study them under a scanning electron microscope to determine the dimensions of these fibers. An SEM is available in the Kasha laboratory on campus. A prior study found that Cladophora (a separate species of algae) had fibers roughly 37-55 mm in diameter that were longer than the fibers found in cotton (the control group), so this study would help us hypothesize how effective the fibers will be in helping tie together the concrete’s particles.

We will additionally use x-ray diffractometry (XRD) to measure the crystallinity of the

CNFs, since the molecular structure of the CNFs affect their macroscopic behavior, which could affect the theoretical reinforcement of pervious concrete. After all, both diamonds and coal are made of carbon with different bonds between the atoms. An X-ray diffractometer is available at the MagLab in Innovation Park.

We may (time and resources permitting) also use Fourier Transform Infrared Spectroscopy (FT-IR) to determine the chemical compositions of the CNFs by plotting the absorption of infrared waves.